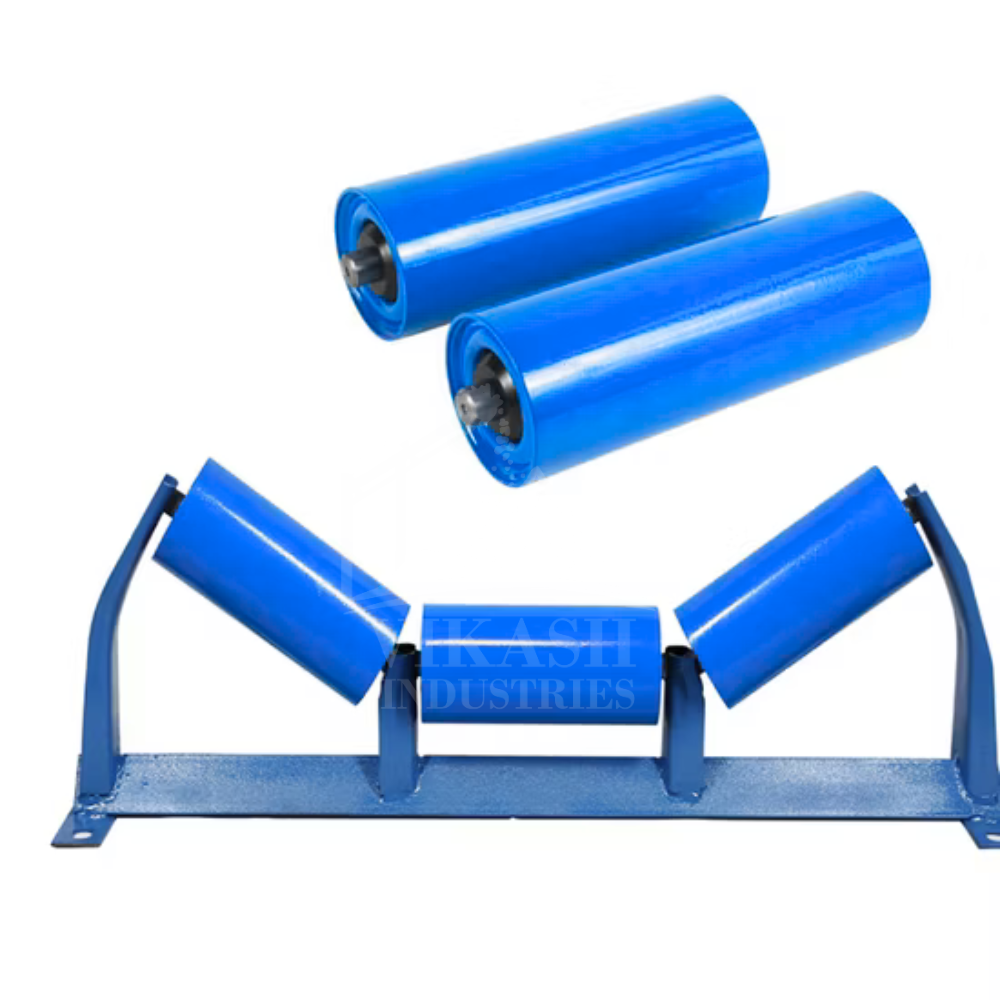

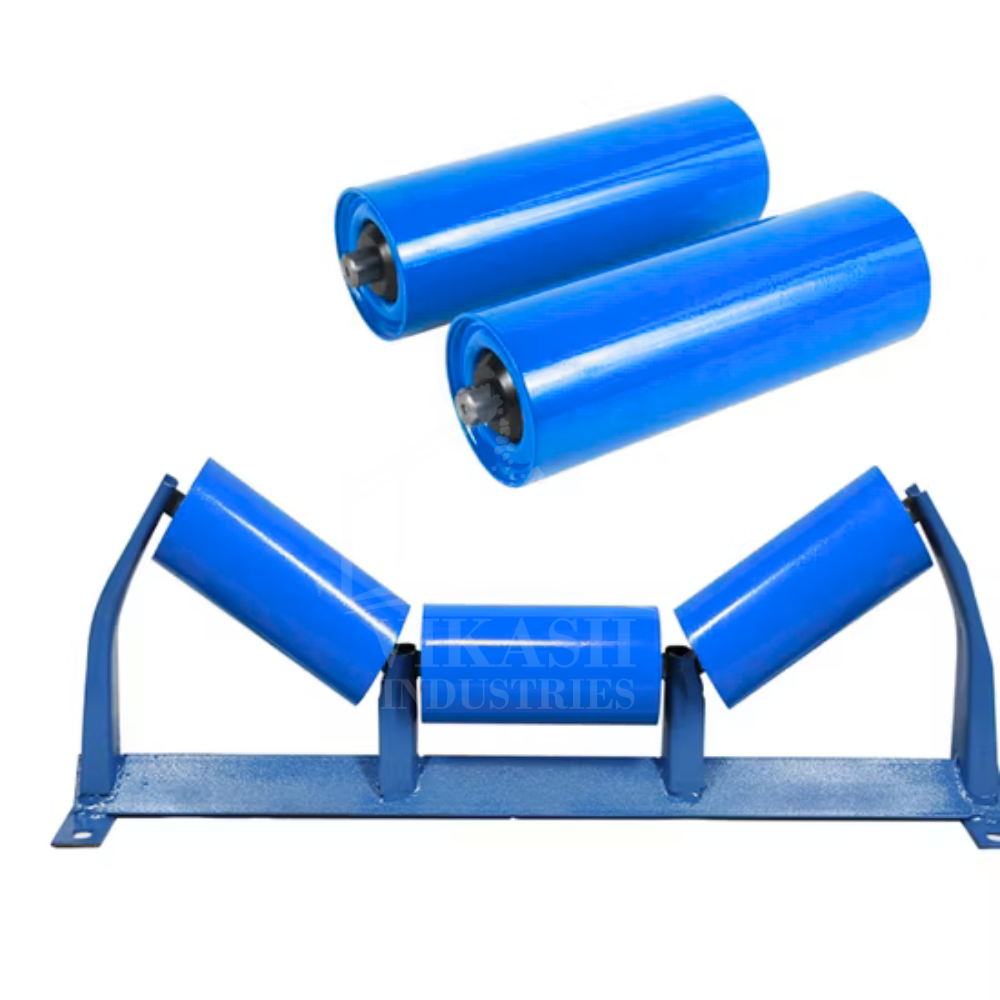

conveyor idler roller

Product Details:

- Usage & Applications Conveyor systems material handling equipment

- Shape Cylindrical taper design

- Size 600-1600mm

- Features Durable corrosion-resistant lightweight

- Surface Finish Smooth finish

- Product Type Machine Spare Part

- Material Composite material

- Click to View more

conveyor idler roller Price And Quantity

- 20 Piece

- 600.0 INR/Unit

conveyor idler roller Product Specifications

- Composite material

- Durable corrosion-resistant lightweight

- 600-1600mm

- Machine Spare Part

- Conveyor systems material handling equipment

- 600 Millimeter (mm)

- Cylindrical taper design

- Smooth finish

- 10 Kilograms (kg)

- Blue

conveyor idler roller Trade Information

- 5 Days

Product Description

At Vikash Industries, our conveyor idler rollers are engineered to ensure smooth belt movement, reduced friction, and long-term operational reliability. Designed to perform in demanding material handling environments, our idlers support efficient bulk material transport while minimizing belt wear and maintenance requirements.

Manufactured using high-quality raw materials and precision-engineered components, Vikash Industries idler rollers deliver consistent performance under heavy loads, high speeds, and harsh operating conditions.

Types of Conveyor Idler Rollers

Carrying Idlers

Designed to support the loaded side of the conveyor belt, our carrying idlers provide stable belt alignment and efficient material flow, ensuring smooth and uninterrupted conveying operations.

Impact Idlers

Installed at loading points, impact idlers are equipped with shock-absorbing rubber rings that protect the conveyor belt from heavy impact loads, reducing belt damage and extending service life.

Return Idlers

Used on the return side of the belt, return idlers maintain proper belt tracking and reduce sagging, ensuring smooth belt return with minimal vibration and wear.

Engineering & Build Quality

Our idler rollers are manufactured with:

-

High-strength steel pipes

-

Precision-machined shafts

-

Sealed-for-life bearings

-

Effective dust and moisture sealing systems

This construction ensures low rolling resistance, quiet operation, and long service life even in dusty and abrasive environments.

Key Benefits

Smooth belt travel with reduced friction

High load-bearing capacity

Excellent resistance to dust, moisture, and corrosion

Reduced belt wear and power consumption

Long service life with minimal maintenance

Compatible with standard conveyor structures

Applications

-

Stone Crushing Plants

-

Mining & Quarry Operations

-

Cement Plants

-

Power Plants

-

Bulk Material Handling Systems

Reliable Material Handling by Vikash Industries

With a commitment to quality, precision, and performance, Vikash Industries conveyor idler rollers are trusted for dependable operation and long-term value across industries.

Engineered for endurance. Trusted for performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS